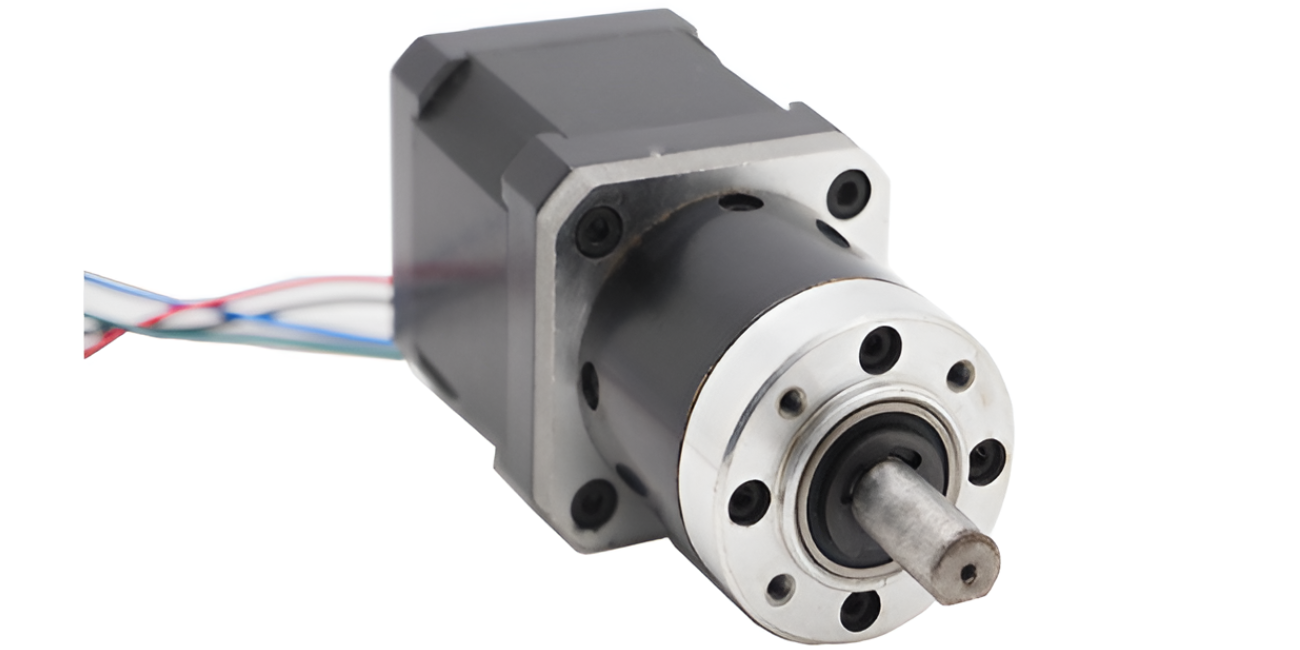

Unleash High-Torque Precision: Exploring the NEMA17 Planetary Geared Stepper Motor (25 kg.cm, 1:14 Reduction)

In the realm of motion control, where accuracy and power are paramount, the NEMA17 PLANETARY GEARED STEPPER MOTOR 25 KGCM REDUCTION RATIO 1:14 stands out as a formidable contender. This compact yet mighty motor combines the precise stepping capabilities of a NEMA17 stepper with the torque-multiplying prowess of a planetary gearbox. For robotics enthusiasts, CNC builders, 3D printing aficionados, and automation engineers, this geared stepper motor offers a compelling solution for demanding applications.

This blog post will delve into the intricacies of this powerful motor, exploring its key features, benefits, and the diverse range of projects where its exceptional torque and precision can truly shine.

Decoding the Powerhouse: Understanding the Specifications

Let's break down the key elements of this motor's description:

- NEMA17: This refers to the standardized frame size of the stepper motor (approximately 1.7 x 1.7 inches or 42.3 x 42.3 mm). NEMA frame sizes ensure mounting compatibility across different manufacturers.

- Planetary Geared: This indicates the type of gearbox integrated with the stepper motor. Planetary gearboxes are known for their compact design, high efficiency, and ability to deliver significant torque amplification within a relatively small footprint. They achieve this by using multiple planet gears orbiting a central sun gear, all enclosed within an outer ring gear.

- 25 kg.cm: This crucial specification denotes the holding torque of the geared stepper motor. Holding torque is the maximum torque the motor can withstand without slipping when it is energized but not rotating. A substantial 25 kg.cm translates to significant rotational force, capable of handling demanding loads.

- Reduction Ratio 1:14: This specifies the ratio by which the gearbox reduces the output speed of the stepper motor while proportionally increasing its torque. A 1:14 reduction means that for every 14 rotations of the stepper motor shaft, the output shaft of the gearbox rotates once. This trade-off between speed and torque is precisely what makes geared steppers so powerful.

The Synergy of Precision and Power: Key Benefits

The integration of a planetary gearbox with a NEMA17 stepper motor yields several significant advantages:

- High Torque Output: The primary benefit of the gearbox is the substantial increase in output torque. The 1:14 reduction amplifies the inherent torque of the NEMA17 motor, allowing it to drive heavier loads and overcome greater resistance.

- Enhanced Precision: While the gearbox reduces the output speed, it often improves the positional accuracy and repeatability of the system. The gear reduction minimizes the impact of motor step inaccuracies on the final output.

- Compact Design: Planetary gearboxes are known for their coaxial design, meaning the input and output shafts are aligned. This results in a more compact and space-efficient motor assembly compared to other types of gearboxes.

- Increased Resolution: The gear reduction effectively increases the angular resolution of the motor. With a 1:14 ratio, each step of the motor translates to a smaller angular movement at the output shaft, leading to finer control.

- Improved Holding Torque: The gearbox also contributes to a higher holding torque, making the motor more resistant to external forces when stationary.

- Durability and Efficiency: Planetary gearboxes are generally robust and efficient, ensuring reliable performance and minimizing power loss.

Applications Across Industries: Where High Torque Precision Excels

The NEMA17 PLANETARY GEARED STEPPER MOTOR 25 KGCM REDUCTION RATIO 1:14 finds its niche in a diverse range of applications that demand both precise positioning and significant force:

- Robotics: Driving robotic arms, joints, and wheeled platforms requiring precise movements under load.

- CNC Machines: Powering axes in CNC routers, milling machines, and laser cutters where accuracy and high cutting forces are essential.

- 3D Printers: Driving the extruder and axis movements, particularly in larger printers or those handling heavier print heads.

- Automation Systems: Implementing precise linear or rotary motion in industrial automation equipment.

- Medical Equipment: Actuating precise movements in medical devices and laboratory automation.

- Telescope Mounts: Providing accurate tracking for astronomical observation.

- Camera Gimbals: Stabilizing and precisely positioning cameras for smooth video capture.

Choosing the Right Powerhouse: Considerations for Your Project

When considering this geared stepper motor for your project, it's essential to evaluate:

- Torque Requirements: Ensure the 25 kg.cm holding torque meets the demands of your application under the maximum expected load.

- Speed Requirements: The 1:14 reduction will decrease the maximum output speed. Verify if the resulting speed is sufficient for your needs.

- Resolution Requirements: Determine if the increased resolution provided by the gearbox aligns with the positional accuracy needed for your application.

- Driver Compatibility: Select a stepper motor driver that is compatible with the NEMA17 motor and can provide the necessary current and control signals.

- Mounting and Integration: Ensure the NEMA17 frame size and mounting options are suitable for your mechanical design.

Conclusion: Empowering Precision Movement

The NEMA17 PLANETARY GEARED STEPPER MOTOR 25 KGCM REDUCTION RATIO 1:14 is a powerful and precise motion control solution. Its ability to deliver high torque in a compact form factor, coupled with enhanced resolution, makes it an ideal choice for a wide array of demanding applications. By understanding its specifications and benefits, you can harness its capabilities to bring your most ambitious projects to life with accuracy and force.